Eco-friendly, Cement-free Materials for 3D Printed Homes

Apis Cor’s vision is to transition to eco-friendly, cement-free 3D print materials.

Due to the novelty and different physical properties of extruded “concretes,” construction 3D printing technology unlocks the opportunity to use alternative materials such as geopolymers.

Apis Cor has successfully tested geopolymer materials in the past and has the technology roadmap to introduce this material and even transition completely to geopolymers in the future. We strongly believe in advanced material science.

What are geopolymers?

3D printing technology opens new horizons for material science. 3D print material can be created in many different ways with a variety of mix designs to handle unique requirements and applications. Apis Cor’s focus is to transition to even more eco-friendly materials which do not contain cement as a binder. (You may not know, cement production contributes to greenhouse emissions.) Cement is a well-documented industry standard, but imagine if there was another material which could eliminate the need to use cement at all. Thankfully, such a material already exists - geopolymer concrete.

Geopolymers are inorganic materials with a polymer structure of molecules. They possess high strength and a range of properties. They are called "GEOPOLYMERS" because the raw materials used for their production are mainly minerals of geological origin.

French chemist Joseph Davidovits coined the term "geopolymer" in 1978. Examples of geopolymer cement used in construction can be found in Australia, Ireland, and the United States, to name a few. For instance, in 2014, an entire airport in Brisbane, Australia, was constructed with a concrete based on geopolymer binders. In the United States, special high-strength geopolymer concretes have even been used for airfield and road repair.

Geopolymer concrete is chemically inert to a range of aggressive substances and remains sturdy in severe climates. In comparison to traditional portland cement, geopolymer concrete has been shown to be stronger in tension and compression, it’s more durable and resistant to abrasion, it has better freeze-thaw resistance, and it’s more fire resistant and can withstand temperatures over 1,800°F. Geopolymer concrete provides superior thermal insulation which reduces household energy consumption, and it’s corrosion resistant, even with aggressive substances including some types of acids. Another advantage is that geopolymer concrete develops about 50% of its strength in the first three days, which significantly increases construction speed. Geopolymers have excellent waterproof properties thanks to its inherent mesoporous structure, large molecules like water can't enter in the geopolymer matrix even if they are pushed by external forces.

The list of benefits goes on and on, but the most important feature of geopolymers is that they are a much more environmentally friendly alternative to Portland Cement. Geopolymer concrete can be produced by re-using and recycling waste and industrial by-products from existing industries that would otherwise end up in the landfill. This means there’s no need to mine additional natural resources. Geopolymer cement reduces CO2 emissions by up to 90% compared to portland cement production and it is much more recyclable.

Apis Cor has been developing and experimenting with geopolymer 3D print material since 2018 and we have seen some impressive and promising results.

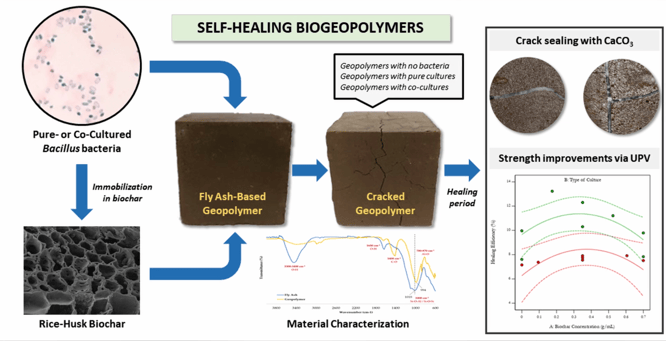

In addition to geopolymers, there have been recent breakthroughs in self-healing concrete and mortars, which have the ability to automatically repair themselves when cracking occurs. Some self healing concrete contains tiny capsules of fibers which break open and release binding agents when cracks begin to form or are exposed to water. Other types contain special bacteria or fungal spores which can lie dormant for hundreds of years and activate when exposed to water after cracks begin to form. These bacteria and fungi produce the mineral calcium carbonate, which as you remember from section 8.2, is a key component of cement. This binds the crack and forces the water back out, which triggers these bacteria and fungi to die off and release new spores, which will again lie dormant and wait for the next crack to form.

In addition to geopolymers and self-healing print materials, we also plan to offer a wide array of colored materials with dyes and pigments, as well as a variety of tailored material options for increased durability and for use in more extreme environments. Before long, our printers will be extruding regolith from the moon and mars as we begin paving the way for human colonization on planets far beyond our own.

Superior physical properties.

.png?width=630&name=Self%20Healing%20Biogeopolymers%202%20(1).png)

As an example, properties for rock-based geopolymer cement (Ca,K)-poly(sialate-disiloxo):

- shrinkage during setting: < 0.05%, not measurable.

- compressive strength (uniaxial): > 90 MPa at 28 days (for high early strength formulation, 20 MPa after 4 hours).

- flexural strength: 10–15 MPa at 28 days (for high early strength of 10 MPa after 24 hours).

- Young Modulus: > 2 GPa.

- freeze-thaw: mass loss < 0.1% (ASTM D4842), strength loss <5 % after 180 cycles.

- wet-dry: mass loss < 0.1% (ASTM D4843).

- leaching in water, after 180 days: K2O < 0.015%.

- water absorption: < 3%, not related to permeability.

- hydraulic permeability: 10−10 m/s.

- sulfuric acid, 10%: mass loss 0.1% per day.

- hydrochloric acid, 5%: mass loss 1% per day.

- KOH 50%: mass loss 0.02% per day.

- ammonia solution: no observed mass loss.

- sulfate solution: shrinkage 0.02% at 28 days.

- alkali-aggregate reaction: no expansion after 250 days (−0.01%), as shown in the figure, comparison with Portland Cement (ASTM C227). These results were published in 1993.[43] Geopolymer binders and cements even with alkali contents as high as 10% do not generate any dangerous alkali-aggregate reaction when used with an aggregate of normal reactivity.[44]

Want to learn more about emerging and novel technology?

Sign up for Apis Cor University to get access to comprehensive online courses! In the online courses, you will learn about the different types of construction 3D printing technology, advantages over traditional construction techniques, and learn how to actually 3D print a house! The courses are designed for all levels of experience - from novice students to sophisticated industry professionals. Learn from our experience delivering the Guinness World Record for the largest 3D printed building, the first commercially permitted 3D printed building in America (Boca Chica, TX), as well as multiple NASA awards and residential buildings, including one in MO, USA.

Sign up for the online courses here and join the construction revolution!